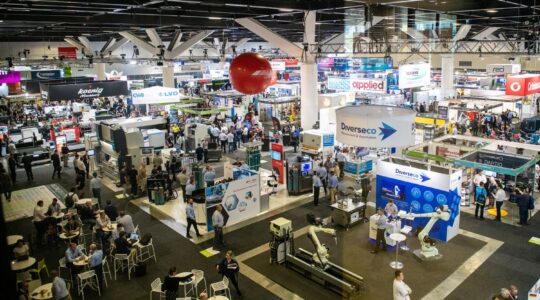

Australian manufacturers are adopting Artificial Intelligence in their operations quicker than their North American and United Kingdom counterparts, according to an international survey of more than 1500 businesses.

Rockwell Automation’s 2024 State of Smart Manufacturing report also reveals the emergence of Causal AI to complement Generative AI (Gen AI) in the manufacturing space and a looming “Industrial Metaverse” which will drive onshoring and support local supply chains.

The report said companies were using Gen AI to develop and test products in a virtual immersive environment, with Causal AI used to learn cause and effect relationships within data and then used to inform the output of AI models.

Rockwell said a report by the World Economic Forum offered this as a type of question that Causal AI models were well placed to answer: “What caused this issue in my manufacturing plant and what actions can I take to prevent future issues?”

Rockwell’s South Pacific Regional Director Anthony Wong said Australian companies were already embracing GenAI and Causal AI, with even wider adoption expected.

The report surveyed more than 1500 manufacturers across 17 countries, including 88 businesses in Australia and New Zealand.

Of the manufacturers in Australia and New Zealand, 45 percent reported the wide adoption of Gen AI and Causal AI with another 34 percent planning to invest within the next two years.

Mr Wong said Gen AI and Causal AI implementation in Australia and New Zealand was already higher than in Canada (37 percent), UK (41 percent), and the US (43 percent).

The report also found the Metaverse, which was popularised in social media, had been embraced by industry, which has incorporated the principles to benefit manufacturing and allied sectors.

It suggested the Industrial Metaverse was being constructed with existing tools, including digital twins, artificial intelligence, high-fidelity simulations, extended reality, blockchain, 5G connectivity, and cloud and edge computing, which will lead to manufacturing being localised and supply chains becoming more resilient.

“In the Industrial Metaverse, machines, factories, grids, and systems are mirrored in the virtual world. This enables teams to collaborate in real time regardless of distance,” Mr Wong.

“Taking this to the next level will need cloud technology, AR, and VR systems, blockchain, AI, and other technologies to come together.”

The report suggests the manufacturing sector is set for phenomenal growth.

In the next 12 months, 50 percent of the Australian and New Zealand companies surveyed, planned to invest in the Industrial Metaverse.

Australia was bullish about this technology and ahead of other countries where planned investment levels were significantly lower – Canada (30 percent), Germany (34 percent) and the US (42 percent).

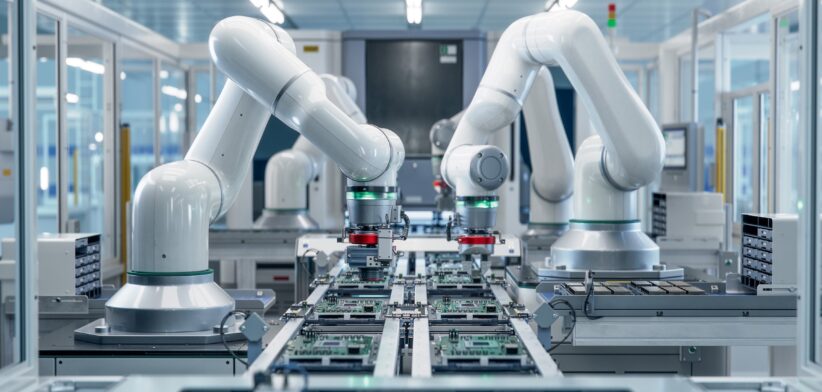

The report also found companies were looking to counter the tight labour market through robotics, with nearly all companies surveyed looking at options.

Around 40 percent of Australian and New Zealand businesses surveyed had already implemented robotics at scale, with 33 percent piloting robotics implementations and another 23 percent at the planning stage.