A new process to extract lithium without water or chemicals and with minimum energy has been developed by an Australian company.

ElectraLith, a Monash University spinout company, has proven its Direct Lithium Extraction and Refining (DLE-R) technology which produces green battery-grade lithium hydroxide.

CEO Charlie McGill said the DLE-R technology could produce lithium hydroxide from a range of lithium sources including salar brines, geothermal oilfield brines and spodumene leach in locations across the US, Argentina and Australia.

Mr McGill said the technology met a significant and urgent global demand to reduce the economic and environmental costs of lithium production, which was an essential element in “clean energy”.

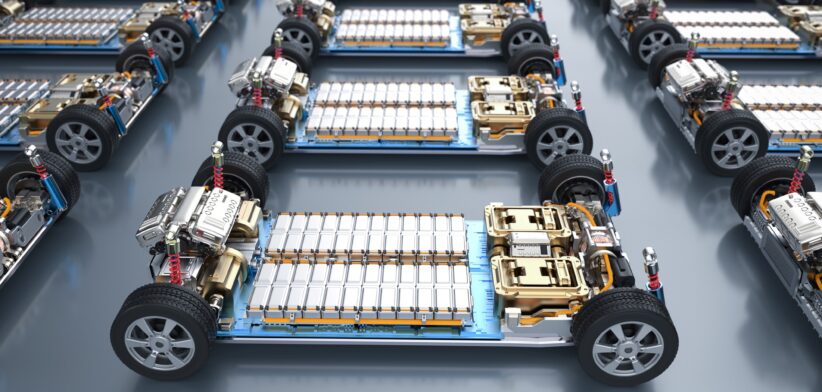

“It is used to make batteries for electric vehicles and wind and solar power storage. Most processes to extract lithium are costly and have negative impacts on the environment such as carbon dioxide emissions, mineral waste, chemical pollution and the subsequent alteration of the hydrological cycle from the use of vast quantities of water.”

He said the DLE-R used electro-membrane and electrodialysis technology to extract and produce battery-grade lithium hydroxide in a single, scalable and modular step.

“Other DLE technologies generally require further processing and energy to produce a usable lithium chloride product.”

Mr McGill said ElectraLith’s patented DLE-stage membranes were based on work conducted by Professor Huanting Wang within the Monash University Faculty of Engineering.