A zero-emissions system which produces ammonium, needed for fertiliser, from wastewater has been developed by Australian researchers.

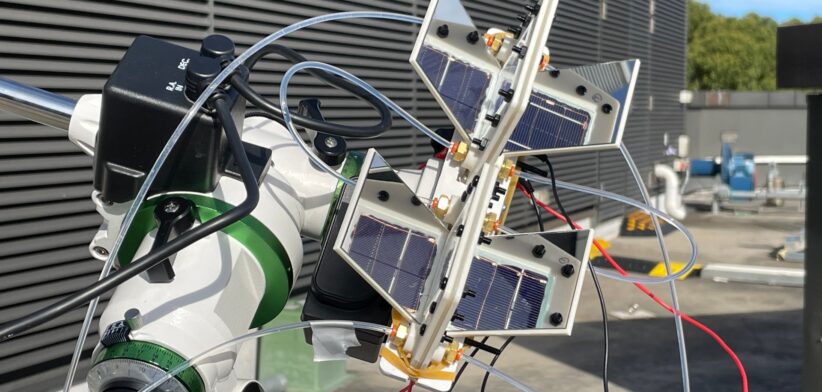

Engineers from UNSW Sydney used a solar panel to create an artificial leaf that turned nitrate wastewater into ammonium nitrate.

Professor Rose Amal said ammonia was essential for producing fertilisers that supported global agriculture and food production.

“However, the traditional way of making it creates large amounts of greenhouse gas emissions, since fossil fuels are required for the hydrogen production and the energy to power the high-temperature process,” Professor Amal said.

He said a team had now developed a way to generate ammonium ions from nitrate-containing wastewater using only a specially-designed solar panel that worked like an artificial leaf.

“The process is known as photoelectrocatalytics (PEC) and utilises a nano-structured thin layer of copper and cobalt hydroxide on the panel that acts as a catalyst to assist the chemical reaction needed to produce ammonium nitrate from the wastewater.”

Professor Amal said traditional ammonia production required high temperatures, around 400 to 500 degrees Celsius, and high pressure, which historically meant the use of fossil fuels.

“This system works at ambient conditions and just uses sunlight to produce ammonium from nitrate-containing wastewater.

“We think this new technology could be implemented on a relatively small scale in agricultural locations to produce ammonium onsite, which would decentralise the production process and further reduce CO2 emissions that are associated with the transportation process.”

He said in a real leaf, photosynthesis was the way that plants used sunlight, water, and carbon dioxide to create oxygen and energy in the form of sugar.

“In this new photoelectrocatalytic process, the solar panel is acting like an artificial leaf to use sunlight, and nitrate-containing wastewater to create ammonium nitrate.”

Read the full study in the Journal of Energy and Environmental Science.