Recycling lithium-ion batteries to recover their critical metals has lower environmental impacts than mining for the metals.

New research from Stanford University, in California, quantified the environmental footprint of the recycling process, and found it emitted less than half the greenhouse gases (GHGs) of conventional mining and refinement of critical metals.

Assistant Professor William Tarpeth said recycling also used about one-fourth of the water and energy of mining new metals.

Assistant Professor Tarpeth said on a large scale, recycling could help relieve the long-term supply insecurity – physically and geopolitically – of critical battery minerals.

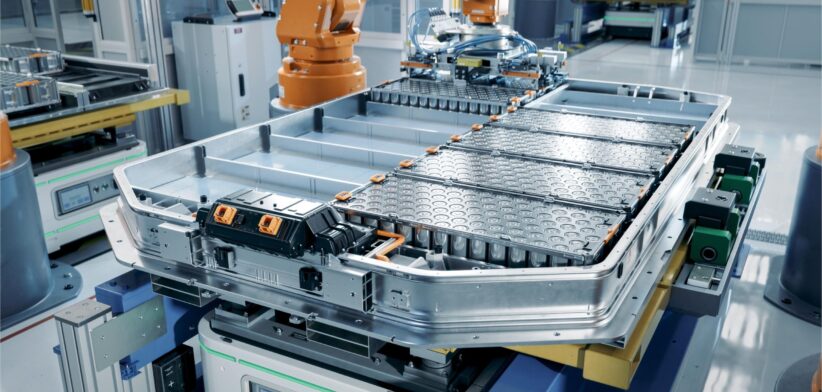

He said lithium-ion battery recyclers extracted lithium, nickel, cobalt, copper, manganese, and aluminium from the accessing the “scrap stream”.

“This study tells us that we can design the future of battery recycling to optimize the environmental benefits.”

Study co-author Samantha Bunke, a PhD student, said battery recycling’s environmental impacts depended heavily on the processing facility’s location and electricity source.

“A battery recycling plant in regions that rely heavily on electricity generated by burning coal would see a diminished climate advantage,” Ms Bunke said.

“On the other hand, fresh-water shortages in regions with cleaner electricity are a great concern,” added Bunke.

She said transportation was a crucial factor when assessing the impact of mining operations, with most of the mines in Australia, Africa and South America, with the need, in many cases, to then transport raw materials to China for processing and refinement.

Read the full study: Life cycle comparison of industrial-scale lithium-ion battery recycling and mining supply chains.