A skincare ingredient has been used to create a new electricity-conducting material which the Australian developers say will revolutionise smartphones and wearable technologies.

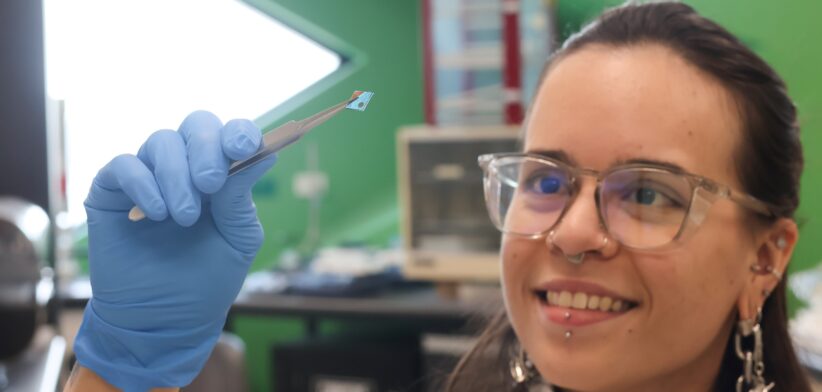

Scientists at Melbourne’s La Trobe University have used hyaluronic acid, well known due to its popularity in skincare, in a new technique on gold plating to create a thinner, more durable film used to conduct electricity in devices like biosensors.

Lead researcher Associate Professor Wren Greene said the technique could lead to major improvements in the function, cost and useability of devices like touchscreens and wearable biosensors.

“Conductive polymers as we know them were developed nearly 50 years ago and although they’re exciting, they haven’t lived up to their potential in that time,” Dr Greene said.

“Often they are difficult to fabricate, as thin films don’t conduct electricity very well, aren’t transparent and can have highly variable properties,” he said.

“Through our method, called ‘tethered dopant templating’, we’ve created a robust way of making a conductive polymer that is flexible, durable, can conduct electricity as well as metals and is easily reproduced – so it’s scalable.”

Dr Greene said conductive polymers were synthetic materials widely used across all smart devices, from touch screens on smartphones to medical devices that regulated a patient’s drug dosage and delivery.

He said the new research disproved the longstanding belief that to create conductive polymers, substances like hyaluronic acid must be added to a mixture of water and polymer-forming particles.

“Applying the hyaluronic acid directly to the gold, in fact, gave scientists total control over the material’s conductive properties, its shape and appearance.”

Read the full study: A Scalable Synthetic Approach for Producing Homogeneous, Large Area 2D Highly Conductive Polymers.