A flexible solar cell manufacturing facility has opened in Victoria to fast-track development of the technology.

Operated by the CSIRO, the complex can produce thousands of cells a day to be fine-tuned and enhanced.

CSIRO Executive Director, Digital, National Facilities and Collections Professor Elanor Huntington said the cutting-edge $6.8 million facility was dedicated to taking the group’s printed flexible solar technology out of the lab and into the real world.

Professor Huntington said unlike traditional silicon solar panels, the flexible solar cells were printed on thin plastic films.

She said this made them lightweight, portable, and suitable for various applications across urban construction, space, defence, mining, emergency management, disaster relief, and wearables.

“Through CSIRO’s new Printed PV Facility, industry partners can access both researcher expertise and specialised equipment to improve and apply flexible solar technology in novel ways, anywhere there is sunlight.

“This not only offers incredible opportunities for Australian manufacturers, but also contributes to addressing global energy challenges and advancing the transition to net zero.”

Leader of CSIRO’s Renewable Energy Systems Group, Dr Anthony Chesman, said printed flexible solar was not intended to replace silicon rooftop panels, but complement them.

“This printed solar technology unlocks entirely new applications for affordable, versatile and sustainable energy generation,” Dr Chesman said.

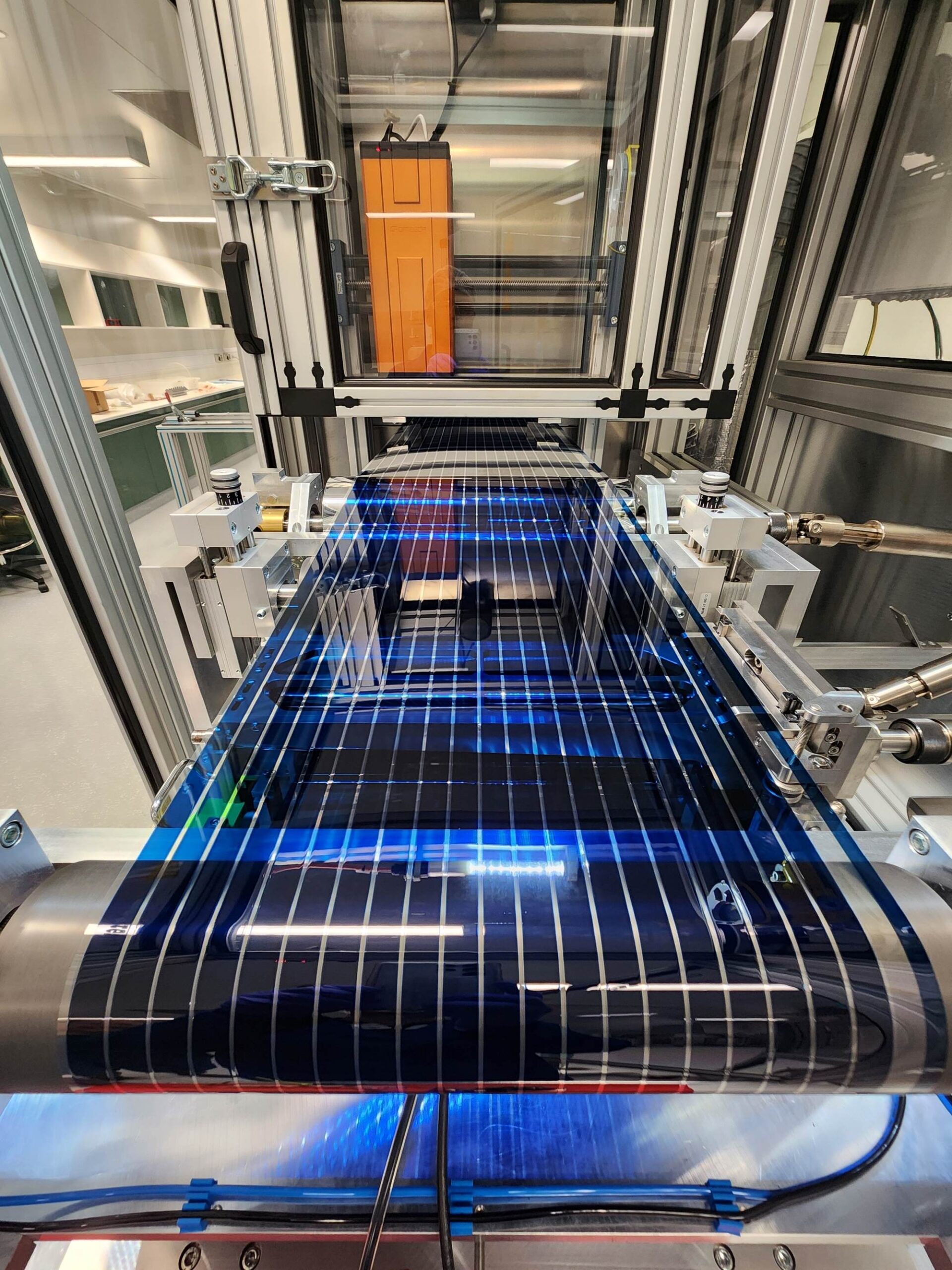

CSIRO’s innovative solar cells were made using an advanced material called perovskite, which is printed on long continuous rolls of flexible film.

“Our new system is highly automated. The multiple printing and laminating steps are performed in a single continuous operation, which significantly cuts down on production costs and the upfront investment needed to get started,” Dr Chesman said.

“Our team has also developed an automated system that can produce as many as 14,000 test solar cells a day to fine-tune their design and performance.

“We’re looking for partners who want to join us on the R&D journey and ultimately take this technology to market.”

Dr Chesman said in addition to printed flexible solar, the lab was equipped to explore other fields that used printable materials for battery and hydrogen technologies.

Learn more about the CSIRO Printed PV Facility.